Can Ceramics Be Polished? Sharing Ceramic Polishing Techniques

Ceramics are used in a wide variety of applications, from household items to industrial components, because of their durability, beauty, and resistance to heat and chemicals. However, during the production process or in everyday use, ceramics can develop problems such as burrs, scratches, and other surface defects. Fortunately, polishing ceramics can restore their original beauty and functionality. In this article, we'll explore the different ways to polish ceramics and share some tips for getting the best results.

Ceramic Polishing Method

There are several effective methods for polishing ceramics, each with its own advantages and uses. Here are the main techniques:

1. Manual polishing method:

Tools required: File, sandpaper and polish.

Process: This method involves manually polishing the ceramic surface using hand tools. Use coarser sandpaper first to remove larger imperfections, then gradually use finer sandpaper to achieve a smoother surface.

Cutting edge:

Work slowly and patiently to avoid over-polishing or damaging the ceramic.

Use circular motions to ensure even results.

Clean the surface frequently to remove dust and debris that may cause scratches.

2. Mechanical polishing method:

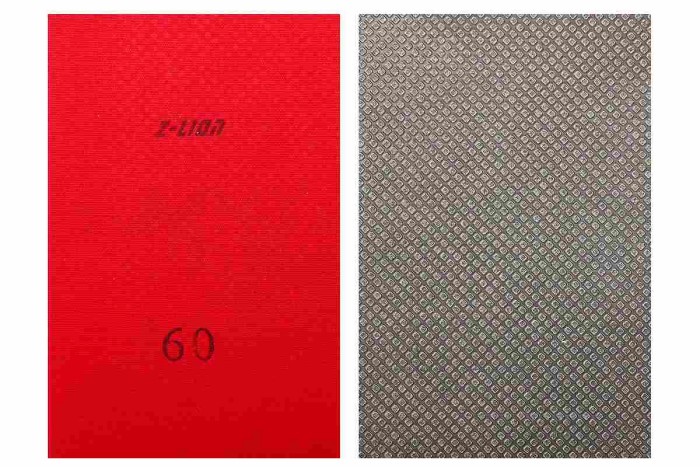

Tools required: Power grinder, polisher and polishing pad.

Process: Mechanical polishing uses a power tool to achieve a more even, efficient polish. Mount the polishing pad to the grinder and apply a suitable polishing compound. Move the tool across the surface in a consistent pattern.

Cutting edge:

Start with a lower speed setting to avoid overheating the ceramic.

Use a polish designed for ceramic for best results.

Before starting the polishing process, make sure the surface is clean and free of debris.

3. Chemical polishing method:

Tools required: Chemical polish (acid or base), protective gear (gloves, goggles), and applicator.

Process: This method involves etching the surface of the ceramic using chemicals to remove imperfections and achieve a polished effect. When using chemicals, the manufacturer's instructions and safety guidelines must be followed.

Cutting edge:

Test the chemical on a small, inconspicuous area first to make sure it won't damage the ceramic.

Use protective gear to avoid skin and eye contact with chemicals.

Rinse the ceramic thoroughly after polishing to remove any residual chemicals.

Ceramic Polishing Tips

To ensure a successful polishing process, it is essential to master the following skills:

1. Choose the right polishing tool:

Hand polishing: Use appropriate sandpaper (start with coarse grit and gradually move to fine grit) and a file for hand polishing. This method is ideal for small areas or intricate designs.

Mechanical polishing: For larger surfaces or more efficient polishing, a high-speed electric grinder is recommended. Make sure to select the correct type of grinding disc that matches the ceramic material.

Chemical polishing: When choosing a chemical polish, select the appropriate chemical based on the type of ceramic. Always follow safety guidelines and manufacturer instructions.

2. Control polishing force:

Hand polishing: When using hand tools, apply consistent and gentle pressure. Excessive pressure may cause scratches or damage the ceramic surface. Be patient and let the tool do the work.

Mechanical polishing: Pay attention to the compatibility between the processing head and the grinding disc. Avoid over-processing, keep the grinder moving and do not stay in one position for too long, which can cause overheating and damage.

3. Fine processing:

For more complex ceramic products, careful and meticulous work is required. Take your time with the intricate areas, ensuring that polishing imperfections have minimal impact on the overall appearance. Use finer grits and polishes for finishing.

4. Regular inspection:

Throughout the polishing process, periodically inspect the surface to assess progress. This will help you identify any areas that may need extra attention or correction.

5. Apply a protective coating:

After polishing, consider applying a protective coating or sealer to enhance the shine and protect the surface from future damage. This step is especially important for items that will be subject to wear and tear.

Notes on Ceramic Polishing

While polishing ceramics can produce excellent results, it is critical to take certain precautions to ensure safety and effectiveness:

Wear gloves: Always wear gloves during polishing to protect your hands from sharp edges and potential injury. This is especially important when handling tools and chemicals.

Keep the ceramic surface moist: Keeping the ceramic surface moist during polishing helps reduce friction and prevent damage. A moist surface also helps achieve a smoother finish.

Rinse and dry after polishing: After finishing the polishing process, rinse the ceramic product with clean water to remove any residual polish or dust. Gently dry the ceramic with a soft towel, making sure there is no residual moisture, which can cause staining or damage.

Work in a well-ventilated area: If you use a chemical polishing method, make sure you work in a well-ventilated area to avoid breathing in the fumes. Proper ventilation is essential for safety when handling chemicals.

Test in a small area first: Before applying any polishing method (especially chemical polishing), test it on a small, inconspicuous area of the ceramic. This will help you determine if the method is suitable and will not cause damage.

In Conclusion

Polishing ceramics is a valuable skill that can restore the beauty and functionality of ceramic items, whether they are decorative items, tableware or industrial components. By understanding the different polishing methods (manual, mechanical and chemical), you can choose the best method for your specific needs. With patience and the right technique, you can achieve a polish that enhances the look and life of your ceramics. Whether you are a DIY enthusiast or a professional, mastering ceramic polishing can enhance your craft and improve the quality of your work.

-

Online service

-

Official wechat account

-

QQ:40933769

-

E-mail:sales@z-lion.com

Online Message

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.