Resin bonded diamond grinding tools: enhanced stone polishing

When it comes to the intricate art of stone polishing, the quality and precision of the tools used play a key role in achieving stunning results. A very important type of tool in the stone polishing industry is resin resin-bonded diamond grinding tool. These tools are effective in achieving fine finishes and enhancing the beauty of a range of stone materials, including marble and granite.

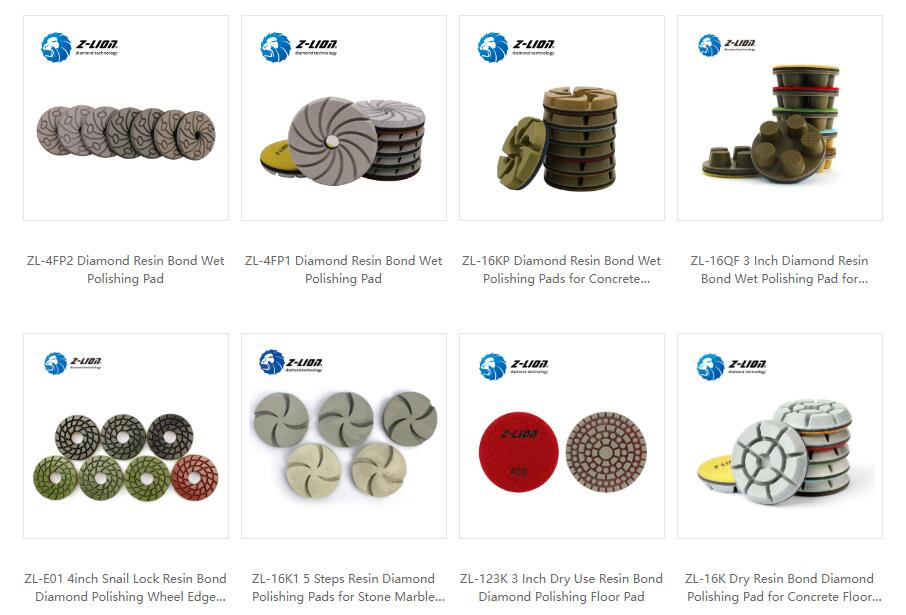

Resin-bonded diamond grinding tools are composed of resin bonds and carefully embedded diamond abrasives and are an integral part of multi-head grinding and polishing production lines. They are vital in the final stages of the stone polishing process, adding finesse and gloss to the stone's surface. Resin-bonded diamond abrasive tools include diamond grinding wheels, diamond drum wheels, diamond grinding discs, and diamond flexible polishing pads. These tools are designed to meet the different stages of the polishing process, from precision grinding to the final stage of obtaining a glossy surface.

One of the main advantages of resin-bonded diamond abrasives is their ability to complement and follow up the work of metal-bonded abrasives. After using metal bond tools to complete the rough grinding, medium grinding, and fine grinding stages, resin abrasive tools intervene to finely process the stone surface. Their custom designs allow them to meticulously remove the smallest amounts of material with outstanding precision and achieve a high-quality polished surface. Resin-bonded diamond discs and wheels are particularly suitable for flat and side polishing of marble and granite. Its intricate design and specialized composition make it ideal for shaping and refining the surface of these gemstones, ensuring a uniform and lustrous appearance.

One of the outstanding features of resin diamond grinding tools is that they generate less heat during the grinding process due to their excellent self-sharpening properties. This unique feature not only ensures consistent polishing results but also reduces the possibility of tool burn during grinding. Additionally, their resistance to grinding wheel clearance clogging further increases their efficiency and durability, making them the first choice for demanding polishing tasks. The elasticity provided by the resin bond also plays a vital role in improving the roughness of the workpiece surface. This elasticity enables the tool to adapt to complex surfaces, ensuring an even and refined finish. Therefore, resin diamond grinding tools are mainly used for fine grinding and polishing, where precision and perfect finish are crucial.

In addition to their excellent performance characteristics, resin diamond grinding tools offer practical advantages during the manufacturing process. Their low curing temperatures, short production cycles, and relatively simple equipment and supply requirements make them an efficient and cost-effective choice for manufacturers. In addition, the excellent flow shape of the resin enables the formation of complex-shaped abrasive tools, thereby expanding the possibilities for complex and customized polishing requirements. Among the many forms of resin diamond abrasives, diamond flexible polishing pads stand out as a versatile and essential component of stone polishing operations. Diamond soft abrasive discs are made of resin as a binder and diamond powder as an abrasive, and are refined using a hot pressing process to become a high-performance tool with multiple uses.

Diamond flexible polishing pads are composed of four key components: diamond abrasives, a bond that fixes the diamond abrasives, a flexible matrix, and a fastening buckle. Its design includes an abrasive working layer on the front and a Velcro suede surface on the back. This multifunctional tool can be used for manual sanding and polishing of lines, curves, and stepped light guide surfaces of natural and artificial granite. It is also vital for the renovation and maintenance of decorative granite surfaces, demonstrating its adaptability and effectiveness in a variety of stone polishing requirements.

Diamond flexible polishing pads are available in different composition ratios and are designed to be attached to a grinder via a joint. This connection allows water to be filled from a water hole in the middle of the joint or from a nearby tank.

Water is introduced for several purposes: cooling the machined surface, removing chips, and promoting a level of pressure on the diaphragm to effectively polish the granite. This integrated water injection system significantly improves the efficiency and quality of the polishing process.

The processing process of diamond flexible polishing pads is carefully divided into four stages: rough grinding, fine grinding, further fine grinding, and final polishing. Each stage of polishing proceeds from coarse to fine, allowing for a systematic and comprehensive approach to achieving a perfect stone surface. The meticulousness of the process is evident as the surface of the granite being polished is repeatedly ground back and forth with finer diaphragms. It is vital to observe whether traces of the previous number have been removed to ensure that each stage of grinding is completed to the required standard before proceeding to the next stage. Special care is required during the final stages of polishing. The granite surface must first be cleaned and then polished by sprinkling a small amount of water. The goal is to polish the surface until the water evaporates, achieving a finish of over 90%. This attention to detail and requirement for precise, high-quality finishes demonstrates the rigor of the stone polishing process using diamond flexible polishing pads.

While the use of water is common practice in flexible polishing pad applications, some workplaces do not allow wet sanding. In this case, a dry sanding disc must be used. These discs have a special bonding design that allows them to peel slightly during the polishing process. This innovative design helps regulate the surface temperature of the processed granite, preventing it from becoming overheated and causing burns. This versatility allows professionals to adapt to a variety of job site requirements and ensures consistent application of high-quality polishing techniques.

In summary, the role of diamond flexible polishing pads in achieving superior stone surfaces cannot be underestimated. Their ability to adapt to different processing stages, coupled with effective water cooling systems and dry grinding options, make them valuable tools in the field of stone polishing. As expectations for flawless stone surfaces continue to increase, diamond flexible polishing pads will become increasingly important in this field, providing a reliable and efficient solution for achieving superior polishing results.

-

Online service

-

Official wechat account

-

QQ:40933769

-

E-mail:sales@z-lion.com

Online Message

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.