Analysis of the use method and application of diamond wet polishing pads

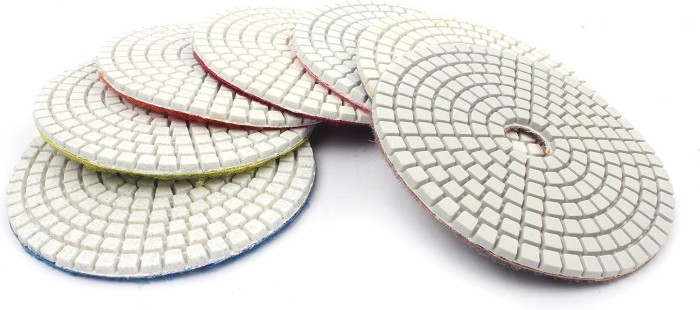

Diamond wet polishing pads are a common abrasive for polishing stone. This type of abrasive uses diamond as the main raw material and is combined with composite materials to make abrasives. It is mainly used for stone, ceramics, glass, floor tiles and other materials. Special-shaped processing and other purposes. Most people don't know much about how to use diamond wet polishing pads. Let's learn about it with Z-LION today.

How to use diamond wet polishing pads?

1. Preparation: Before starting the polishing process, it is important to prepare the surface. Start by using a knife to remove the concrete grout in the gaps between the stones. Next, use a brush, vacuum cleaner, or any other suitable tool to remove dust and debris. To ensure a clean surface, wipe down thoroughly with a clean, dry mop to remove any remaining sand or debris.

2. Start grinding: To start the lapping process, you will need a portable electric or air lapping machine equipped with diamond wet polishing pads. Install the desired pads onto the grinder, making sure they are securely in place. When grinding, it is crucial to apply some pressure on the machine while providing a constant flow of water. This water helps cool the diamond pads and prevents excessive heat build-up. Repeat this motion 4-5 times by moving the grinder back and forth over the surface of the stone to be ground. When finished, replace it with a finer pad and repeat the grinding process. Generally, a total of seven laps with wet polishing pads are required to achieve the desired surface smoothness and flatness. Once sanding is complete, buff the surface with steel wool until the desired brightness and smoothness are achieved. In the process, pay close attention to eliminating any noticeable gaps between the stones.

3. Treat polished floors: Moisture must be removed from the floor after polishing is complete. Use a water suction machine to thoroughly absorb excess moisture from the surface. At the same time, use a hair dryer to ensure that the entire stone floor is sufficiently dry. Natural air drying is also a viable option if time permits, as long as the stone surface remains dry to prevent any potential water damage.

By following the steps below, you can effectively use diamond wet polishing pads to achieve seamless polishing on stone surfaces. Remember that proper surface preparation, constant application of pressure, and the use of water during grinding are key elements to achieving the desired results. With a meticulous approach, you can transform dull and uneven surfaces into stunning works of art that elevate the beauty of any space.

What are the uses of diamond wet polishing pads?

Stone processing: Diamond wet polishing pads are available in a variety of grit sizes, colors, shapes, and sizes for excellent performance in stone working. Whether it's chamfers, lines, curved slabs, or shaped stones, these pads deliver extraordinary results. Their ease of use with a variety of hand grinders is an added advantage that professionals appreciate. An identifiable particle size numbering system allows flexible use to meet specific needs and preferences.

Ground treatment and renovation: Diamond wet polishing pads have proven invaluable for treating and refurbishing floors and steps made of granite, marble, and engineered stone slabs. The flexibility of using these pads with different hand grinders or reconditioning machines adds to the convenience and versatility of the process. Professionals in the field rely on diamond wet polishing pads to enhance the appeal and durability of floors after installation.

Tile polishing: With the help of diamond wet polishing pads, tiles can also be achieved with an unrivaled shine and flawless finish. Whether microcrystalline tile, glazed tile, or antique tile, these pads are compatible with manual and automatic full and semi-polishing machines. This allows a smooth or matte finish to be achieved as desired. The brightness value of a diamond wet grinding disc can exceed 90, which is indispensable in the ground treatment and renovation of various microcrystalline bricks and ceramic tiles. They integrate seamlessly with manual grinders or refurbished machines, offering flexibility based on specific requirements.

Ground renovation: For the refurbishment of concrete floors, including industrial settings, warehouses, car parks, or floors of various aggregate hardeners, diamond wet polishing pads are the first choice. Their application is particularly beneficial for liquid hardener flooring projects, a trend that has gained momentum in recent years. These pads can be easily combined with different hand grinders to meet the specific needs and habits of professionals. Wet polishing pads are available in various grit sizes for rough sanding, fine sanding, and polishing to ensure excellent results in floor refurbishment projects.

The versatility and performance of diamond wet polishing pads are suitable for a variety of applications and are indispensable tools for professionals in various industries. As technology advances and needs evolve, these pads continue to play a vital role in increasing efficiency and delivering superior results. Capable of changing the way stoneworking, floor preparation, tile polishing, and floor renovation, diamond wet polishing pads are truly a powerful asset for professionals looking for exceptional results.

-

Online service

-

Official wechat account

-

QQ:40933769

-

E-mail:sales@z-lion.com

Online Message

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.