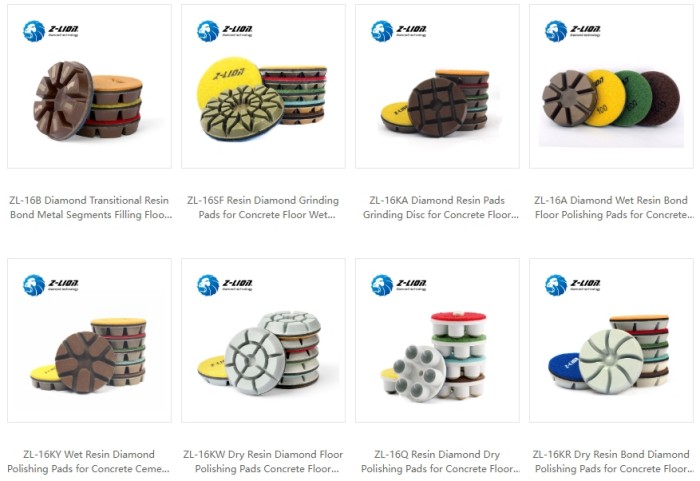

Resin bond diamond grinding wheels Usage Guide

Resin bond diamond grinding wheels are essential tools in various industries, providing efficient and precise grinding capabilities for a variety of materials. Understanding the materials these grinding wheels are made of and their proper use is critical to achieving optimal results and extending their service life.

Material

The production of resin bond diamond grinding wheels involves several key materials, including diamond powder, resin, and metal powder. Diamond powder serves as the main abrasive in the grinding wheel, providing the cutting force required for effective grinding. The resin acts as a binder, holding the diamond particles in place and providing stability during the grinding process. In addition, metal powder is often added to enhance the strength and overall stability of the grinding wheel, ensuring its durability and performance under a variety of working conditions.

Usage

Before using resin bond diamond grinding wheels, they must be prepared for optimal performance. This involves soaking the grinding wheel in water, a process that helps extend its life and improve its grinding efficiency. Once grinding wheels are properly prepared, they can be used in a variety of grinding applications.

When using resin bond diamond grinding wheels, it is important to select the appropriate grinding head size based on the specific requirements of the task at hand. The grinding head should be firmly installed on the grinding head seat to ensure stability and safety during operation. Once the grinding head is in place, it can be positioned over the object to be ground and a certain amount of pressure should be applied to initiate the rotational grinding process.

Basic precautions for using resin bond diamond grinding wheels

1. Safe operation

When using resin bond diamond grinding wheels, safety must be a priority. Operators should wear appropriate protective gear, including safety glasses and masks, to protect themselves from debris and dust generated during the grinding process. This precaution helps prevent potential damage to the eyes and respiratory system and ensures a safe work environment.

2. Stay hydrated

In order to achieve optimal grinding results and prevent overheating and excessive wear of the grinding wheel, they need to be kept moist during use. Water needs to be constantly replenished to ensure that the grinding wheel surface remains sufficiently moist. This practice not only improves grinding performance but also helps extend the life of the grinding wheel.

3. Maintain appropriate pressure

Maintaining proper pressure during the grinding process is critical for efficient and consistent results. Operators should avoid applying excessive pressure as this can cause accelerated wear or breakage of the grinding head. On the contrary, insufficient pressure will reduce grinding efficiency. By maintaining proper pressure, operators can optimize the grinding process while maintaining the integrity of the grinding wheel.

4. Replace the grinding wheel regularly

The wear of resin bond diamond grinding wheels is affected by factors such as frequency of use and hardness of the material being ground. Therefore, the grinding head must be replaced regularly to maintain the grinding effect and work efficiency. By monitoring the condition of the grinding heads and replacing them as needed, operators can ensure consistent performance and maintain high-quality grinding results.

Basic tips for using resin bond diamond grinding wheels

1. Choose the right grinding wheel

Choosing the right grinding wheel is crucial to achieving ideal grinding results. When selecting a grinding wheel, factors such as the hardness, shape, material, and specific requirements of the workpiece should be considered. For harder materials, larger grit wheels are recommended, while workpieces that require grinding of convex or concave areas may benefit from smaller wheel sizes.

2. Control the grinding wheel speed

Controlling the speed of the grinding head is crucial to optimizing the grinding process. According to the specific working conditions, the rotation speed of the grinding head should be adjusted accordingly. When grinding workpieces with higher hardness, the grinding wheel speed should be appropriately reduced. This not only ensures the effectiveness of the grinding process but also helps extend the service life of the grinding head.

3. Reasonable use of waste heat

Resin bond diamond grinding wheels generate heat during the grinding process, which can be effectively utilized. For example, when grinding metal materials, the waste heat of the grinding wheel can be used to heat the metal materials, thereby improving the grinding effect and facilitating heat treatment. By utilizing the waste heat from the grinding wheel, operators can increase the overall efficiency of the grinding process and achieve better results.

-

Online service

-

Official wechat account

-

QQ:40933769

-

E-mail:sales@z-lion.com

Online Message

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.